Understanding the value of data

Data is power. And you are throwing it away if you aren’t making use of it to advance your company in some way. There are many different approaches you can take to better your company by using data. There are many things that can be done to boost productivity and revenue, some of which include gaining an insight of the purchasing patterns of your customers and enhancing the look of your website. However, one cannot only focus on numerical data. The judgments you make about your product strategy and marketing plan may also be improved with the use of data.

What is data engineering all about?

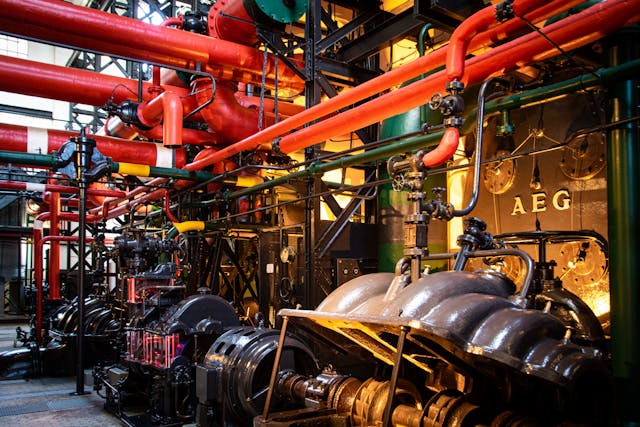

To put it another way, data engineering is the act of developing practical systems that are able to assist in the collection and storage of data from a variety of different sources. This may include anything from correcting inaccuracies in a database to creating it in a more professional light. In its most basic form, it serves as the central pillar of comprehensive business process management. For this reason, data engineering services find applications across a wide variety of sectors, including retail, medical, economics, entertainment, manufacturing, and banking, amongst others.

The industrial sector of the economy may unquestionably benefit immensely from the use of data engineering services. Their services include all aspects of manufacturing, which ultimately ensures the creation of products runs smoothly and that they are delivered to the market at the appropriate time.

Because manufacturing data is often spread on edge devices or other systems both within and outside the plant, accessing this data has historically required transporting enormous amounts of data to centralized storage.

When assisting businesses in meeting the requirements of a large number of customers, Data Engineering Services adheres to the logical approach that is detailed below.

- A significant relationship exists with the service provider dispatching some of its engineers to the locations of the customer for the purpose of knowledge acquisition. This entails gaining a comprehension of the customer’s products and services, as well as their frameworks, software and applications, standards and customs, and, greatest pertinently, establishing collaboration with the customer’s engineering teams.

- When they returned, the engineers integrated the customer’s product development lifecycle into their offshore development procedures by putting in place the necessary systems, processes, and environments. A communication strategy is established, and this assists in transferring data directly between the engineers working for the client and the engineers working for the company in a fluid way. This speeds up the interactions as well as the turn-around time for the execution of the job package.

- The Engineering Professions The involvement of outsourcing in the new product design cycles of long-term strategic clients and the collection of marketing and field inputs are two further ways that outsourcing helps these customers. They connect with consumers at both the beginning and the conclusion of product development and design, which allows them to understand customer wants as well as the challenges that arise in the field after installation.

- Some environmental engineering services draw the in-house expertise they need from the many different universities with whom they have partnerships, as well as from other organisations or entities connected to the aerospace sector. These services guarantee that their data engineers have vast manufacturing knowledge and are able to make an informed on design process, simulations of the cutting process, fixture design, and tooling from the ground up.

- High-quality services in the fields of precision machining, and component, and assembly sourcing are now available to businesses. These services cater to the needs of businesses.

What new ways of using data engineering services are being developed in the manufacturing industry?

Analytics give information about Bharat Result that may be put into action and clearly assist the most important business decisions that a firm must make, such as finding:

- Which product has a smaller margin of profit?

- Which of our suppliers is most likely to cause a disturbance in our manufacturing?

- How does the company compare to its competitors in terms of sales incentives?

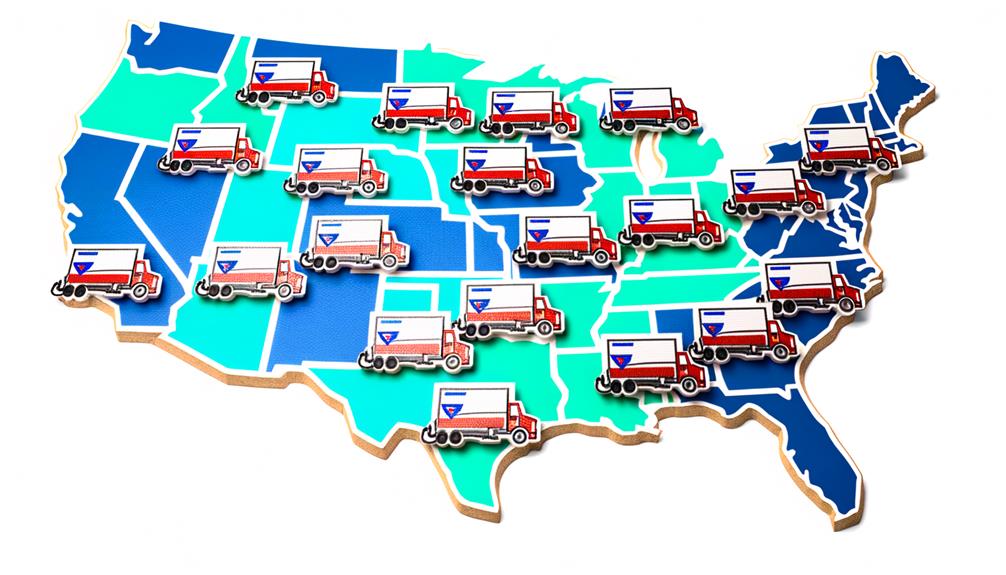

Because goods are often at the core of the production process, the first wave of analytics focuses on enhancing product growth as its primary objective. Other areas that are often focused on include the optimisation of the supply chain, the control of the budget for sales and marketing, the reduction of expenditure on warranties, and general changes to financial planning.

Manufacturers: Data is the way

The integration of internal and external data is becoming an increasingly important strategic need in data-driven production. Manufacturing companies should make use of data engineering services in order to get considerable value while also improving their speed and efficiency as the volume of data continues to dramatically increase. Get in contact with data specialists and get started on your data journey if you are planning to make a major impact via the use of data.