Selecting the right industrial materials is crucial for any project that demands precision, reliability, and long-lasting performance. Among these materials, acetal has become a preferred engineering plastic in various industries due to its strength, dimensional stability, and low friction properties. Whether you are working in manufacturing, automotive production, food processing, or prototyping, choosing the right acetal rod Melbourne supplier plays a key role in determining the success and durability of your end product.

This guide will help you understand what makes acetal a valuable material, what qualities to look for in a supplier, and how to ensure that you are sourcing the right grade and specifications for your specific application.

Understanding Acetal and Its Advantages

Acetal, also known as polyoxymethylene (POM), is a high-performance engineering thermoplastic designed for applications requiring high stiffness, low friction, and excellent dimensional stability. It is widely used in precision parts where tight tolerances and consistent performance are essential. The material remains stable across temperature variations and resists moisture absorption, making it suitable for environments where other plastics may warp or swell.

Common advantages of acetal include:

- High mechanical strength and rigidity

- Excellent wear and abrasion resistance

- Smooth surface finish suitable for moving components

- Low moisture absorption for dimensional accuracy

- Good chemical and fuel resistance

These properties make acetal rods an ideal choice for gears, bushings, bearings, valve components, conveyor parts, machined fittings, and numerous other mechanical applications.

Why Local Sourcing Matters

When searching for acetal rod Melbourne providers, local sourcing often provides significant benefits. Working with a supplier within the region can reduce lead times, minimise shipping costs, and offer better opportunities for communication and customer service. Local providers are more likely to understand regional industry requirements, standards, and environmental conditions that may influence material selection.

Furthermore, having a nearby supplier helps ensure quick turnaround times when urgent replacements or adjustments to project specifications are needed.

Key Factors to Consider When Choosing an Acetal Rod Supplier

Not all suppliers offer the same level of quality, technical expertise, or customer support. When evaluating potential providers, consider the following factors:

1. Material Quality and Certifications

Quality should be your top priority. Ensure the supplier offers genuine, high-grade acetal that meets industry standards. In many cases, certifications such as ISO compliance indicate reliability in material sourcing and processing. Poor-quality acetal may affect machining performance, durability, and product lifespan.

Look for consistency in:

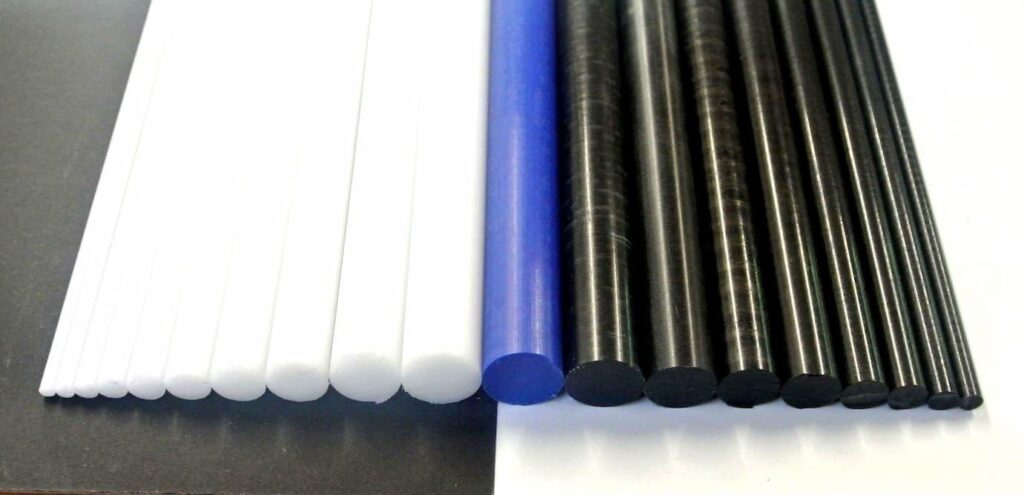

- Colour and finish

- Dimensional accuracy

- Structural uniformity

- Material branding and traceability

2. Range of Sizes and Grades Available

Different applications require different grades. Acetal typically comes in two primary types:

- Acetal Homopolymer (POM-H) – Higher strength and stiffness

- Acetal Copolymer (POM-C) – Better dimensional stability and resistance to chemicals

The best acetal rod Melbourne suppliers will clearly identify the type of acetal they sell and offer a variety of diameters, lengths, and colour options (commonly white, black, and natural).

3. Technical Support and Guidance

If you are unsure which grade or dimension is best for your project, a knowledgeable supplier should be able to advise you. Look for suppliers who provide:

- Machining recommendations

- Design suitability assessments

- Material comparison guidance

- Tolerance advice

Suppliers who understand the technical demands of your industry can help you avoid costly mistakes and material selection issues.

4. Custom Cutting and Machining Services

Some suppliers offer in-house cutting or machining services that can help you save time and reduce waste. If your project requires custom dimensions, this is especially valuable. A provider that can supply rods precisely cut to size improves workflow efficiency and reduces the risk of errors during fabrication.

5. Reputation and Customer Reviews

Reputable suppliers often have a track record of reliability and customer satisfaction. Look for reviews, testimonials, and case studies that demonstrate consistent performance. Businesses that maintain long-term relationships with clients usually indicate trustworthy service and dependable product quality.

Applications Where Acetal Rods Are Most Useful

Understanding your project’s specific demands will guide proper material selection. Acetal rods are commonly used in:

- Automotive components: fuel system parts, clips, and connectors

- Food processing machinery: components that require hygiene and smooth motion

- Engineering prototypes: testing parts before full-scale production

- Consumer products: handles, latches, mechanical levers

- Industrial equipment: rollers, pulleys, and gear wheels

In each of these applications, choosing the right acetal rod Melbourne supplier ensures that the material performs reliably under continuous use.

Maintenance and Longevity Considerations

While acetal is highly durable, proper care extends its lifespan:

- Avoid prolonged exposure to strong acids or oxidising chemicals.

- Use the correct tools and feeds during machining to prevent stress cracking.

- Store rods in a dry, temperature-controlled environment to maintain stability.

Because of its inherent durability, components made from acetal often require minimal maintenance compared to metals or lower-grade plastics. This durability translates to long-term cost savings and improved operational efficiency.

Conclusion

Acetal is a high-performance material valued across industries for its strength, stability, and machinability. However, achieving the best results starts with sourcing material from a reliable supplier who understands your needs and can deliver consistent quality.

By considering product quality, variety of stock, technical support, and supplier reputation, you can confidently choose a provider who meets your project requirements.

Whether you are designing precise mechanical parts, building machinery components, or working on custom engineering solutions, choosing the right acetal rod Melbourne supplier ensures that your final product performs reliably, efficiently, and consistently for years to come.